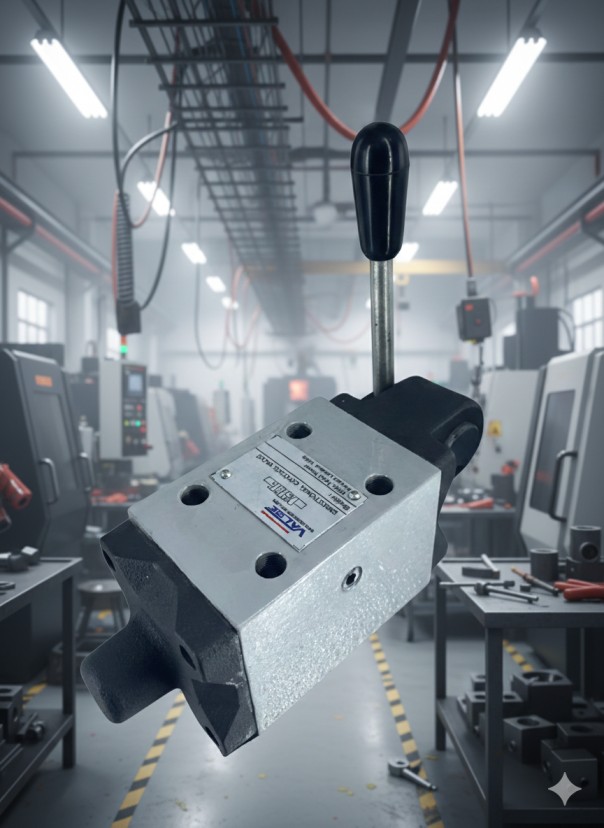

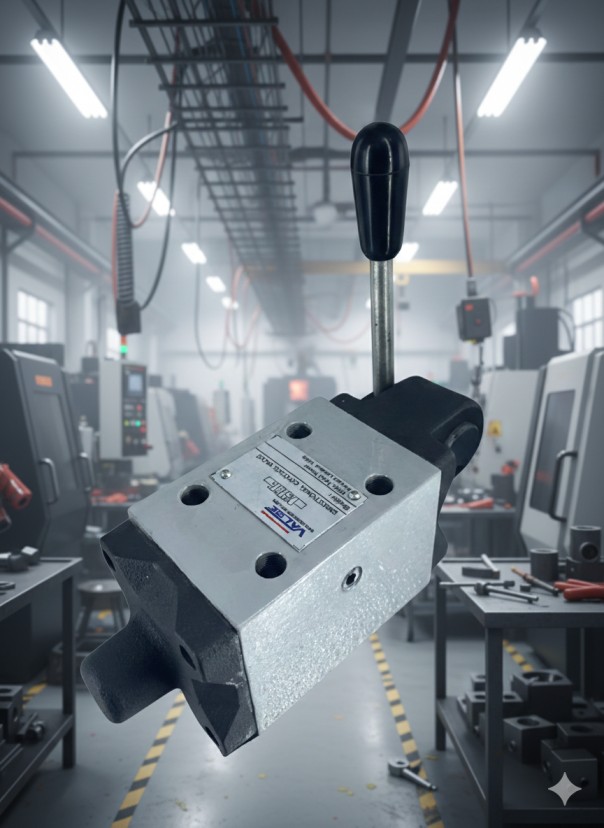

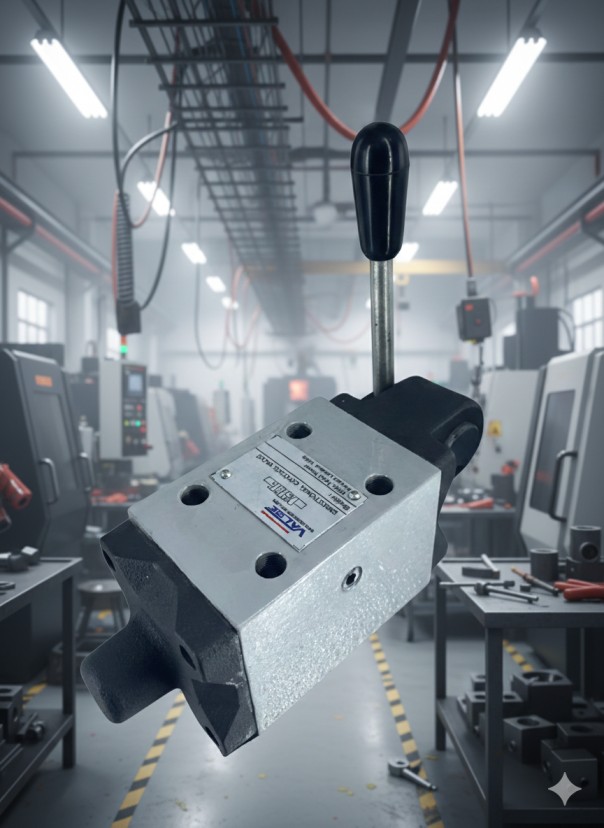

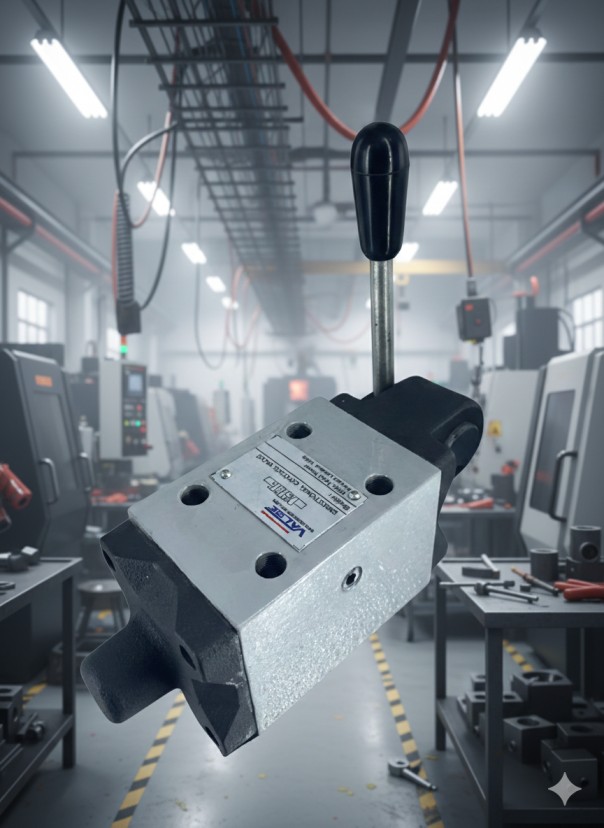

Products Details

Directional Control Valve (Lever Optd.) DCV

Completely encapsulated mechanism for protection against dirt. Five-chamber design for better reduction in dynamic forces and longer valve life. Mounting styles — Sub plate body.

The operating Head Can be Rotated by 90° X 4

Valve mounting interface conforms to International and National Standards

Port configuration conforms to Factory Standards

TECHNICAL SPECIFICATIONS

| 1 | Construction | Spool type |

| 2 | Mounting | Sub plate body |

| 3 | Interface | as per ISO 4401 - AC 05 4 - A and IS 10187, CETOP 05 |

| 4 | Mounting position | Optional |

| 5 | Flow direction | As per spool type. |

| 6 | Operating pressure | For port P, A and B 350 bar. (Standard Valve) |

| 7 | For port P, A and B | 700 bar max.(For special high-pressure valve) |

| 8 | For port T | 100 bar |

| 9 | Hydraulic medium (Both type) | Mineral oil |

| 10 | Viscosity range | 10 cSt to 380 cSt. |

| 11 | Fluid temperature range | -20 °C to +70 °C. |

| 12 | Fluid cleanliness requirement | As per ISO 16/13 or better. |

| 13 | Maximum flow handling | Refer performance curves. (standard valve) Mass |

| 14 | Maximum flow handling capacity | Refer performance curves |

| 15 | Mass (standard valve) | 5.6 kg APPROX (Subplate body). |

| 16 | Performance Curves, Oil used : | ISO VG 68 |

| 17 | Performance Curves, Viscosity : | 68 cSt @ 40º C |

| 18 | Performance Curves, Test : | 50º C. |

Contact

Valse Fluid Power Private Limited

Address

Shed C-3/2, Industrial Estate, Vinobangara, Shivamogga-577204

Call Us

+91 9845926984

Email Us

info@valsehydrulics.com